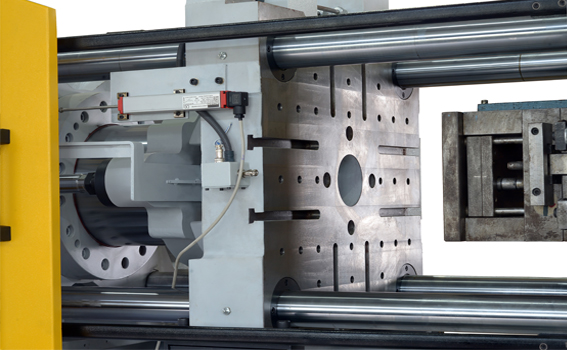

Clamping Unit

Direct hydraulic clamping with robust castings, large ram and rigid structures of moving and stationary platens provide for a deflection free clamping system. This is an

essential requirement for molded part quality and mold life. High quality manufacturing helps to protect the mold even with the highest sensitivity.

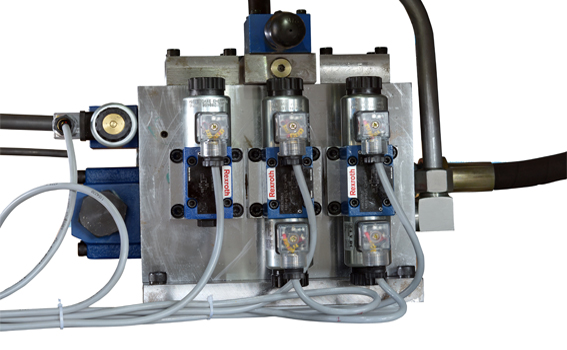

Hydraulics

Clamping and injection hydraulic designs with manifold design placed at appropriate positions bring about best possible hydraulic responses. Variable pump as a standard equipment is ideal for short cycle time and the servo system is an option for long cycle time production. This ensures best levels of power savings.

Injection Unit

A maintenance free double cylinder construction runs on a high quality LM guide. This enables the injection unit to respond to the injection profile to the highest levels and

aids precise repeatability. Close looped injection, as an option, can be utilized for production of high precision industrial parts with graphical injection profiles.

Features

- Direct Hydraulic clamping (Ram Lock).

- Meant for High precision part manufacturing.

- Lowest Maintenance Cost.

- Large platen size for high cavity molds with hot runner system.

- Cartridge Hydraulics makes smooth operation.

- Rigid platens for lowest deflection.

- User friendly controller.

Producing high quality injection molded parts with effective power savings has become a standard requirement. Kestrel has been designed and built to meet these requirements and to deliver quality performance.

STD Equipment

- Direct Hydraulic clamping.

- Infinitely variable clamping force.

- Diret clamp mesurement.

- Mold safety witf 'Slow down' function for smooth mold close.

- Clamp Stroke with Linear Scale.

- Safety door interlock.